Country ham – Luter-style

Published 7:40 pm Friday, April 21, 2023

Story by Phyllis Speidell

Photos by John H. Sheally II and from the Isle of Wight County Museum

Country ham is more than a protein – it is emblematic of a culture that values tradition and taste. While the salty twang of this delicacy can be an acquired taste, country ham aficionados value country ham far above what they may classify as a milder, moister “city ham.”

The earliest English settlers in the coastal areas of what would become Virginia and North Carolina were accustomed to using salt to preserve meat. They quickly learned the Native American techniques of smoking meat and eventually combined both methods to preserve hams with the distinctive flavor and texture prized over the centuries as country ham.

The Jamestown settlers grazed their pigs on Hog Island in the James River, not far from the Smithfield/Isle of Wight/Surry area which became renowned for its fine quality country hams. Working with their individual takes on the smoke/salt method of meat preservation, families devised their own distinctive versions of country ham. The fine points of the process passed down like an heirloom from generation to generation within the family.

Lucy Gwaltney Clay remembers years back when the varied ham tastes were so significant, she could tell, with a few bites, which family cured which ham.

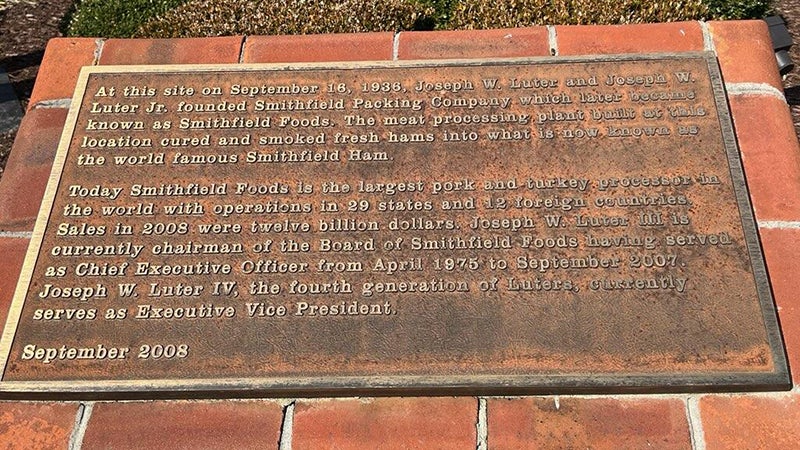

Many of the better-known names in the ham game were local – Todd, Edwards, Joyner, Felts, Darden, Gwaltney and Luter. It was four generations of Luters – Joseph W. Luter, Sr., Joseph W. Luter, Jr., Joseph W. Luter III and Joseph W. Luter IV – who developed perhaps the internationally best known name in hams, as well as sausage and other products. The business the family founded, Smithfield Foods, has become almost synonymous with the town of Smithfield.

The Luter lineage in ham began in 1918 with Luter Sr, a salesman for Gwaltney Packing. When his vision began to fail, he brought along his 10-year-old son, Joseph Luter, Jr., to assist on the sales calls. When Luter Jr. grew into his own job at Gwaltney, he worked up through the various parts of the business to become the plant manager.

Swift & Co. bought Gwaltney in 1926 and made their own changes to the business. By 1936, Luter Jr., unhappy with what he saw as a stalled career, convinced his father to start their own Smithfield Packing Co. — just the two of them, a truck driver and $10,000 from local investors.

Sadly, not long after that, Luter Sr. suffered a stroke. While he remained involved in the business and on the board until his death in 1946, Luter Jr. became CEO of the company, established a packing plant and welcomed the arrival of Joe Luter III, who was born in 1939.

Business flourished through the 1940s. Smithfield Packing hired the legendary Charles Henry Gray, whose 47-year career with the Luters took him from the loading docks to retiring as assistant to the chairman of the board. Gray also developed the famed Charles Henry Gray Party Ham, a popular Smithfield ham with a secret brown sugar glaze.

The company opened a new slaughterhouse just across the Pagan River from what were then the town limits of Smithfield. The curing, however, was still done in town in a building on Commerce Street so that the hams would comply with Virginia law defining Smithfield hams as those processed, treated, smoked, aged, cured by the long-cure, dry salt method and aged for a minimum of six months – all to be done within the corporate limits of the town of Smithfield.

Under Luter Jr.’s leadership, Smithfield Packing grew to 650 employees. Luter III, from his high school days, was among those workers, laboring, just as his father had, on the loading docks and on the kill floor.

From the plant to Wake Forest University, Luter III studied business administration, graduated with a bachelor’s degree in 1962 and came back to work at Smithfield Packing. When Luter Jr. died that same year, his son bought out the non-family shareholders and, in 1966, gained control of the company when he was still in his mid-20s.

Three years later, in 1969, when the company was sold to Liberty Equities Corp., the company name changed to Smithfield Foods Inc. and Luter III left the company to develop a Virginia ski resort, Bryce Mountain. By 1975, however, the company was struggling and asked Luter III to return. He did and restructured Smithfield Foods. Over the next two decades, Smithfield Foods continued to acquire other companies and deal with major environmental concerns while its revenues, however, continued to climb. The company acquired two of the largest hog producers in the country and expanded into Mexico, the United Kingdom and more, becoming the largest pork processor in the world by 2000.

The youngest Luter, Joe Luter IV, was moving up in the ranks to executive vice president of Smithfield Foods and president of Smithfield Packing Company in 2008. The firm continued to innovate and grow. A partnership with Richard Petty Motorsports to sponsor NASCAR Sprint Cup Series events brought even more attention to the company and its products.

Five years later Shanghai International Holdings Ltd., based in China, bought Smithfield Foods Inc. and acquired a majority of shares in the company. C. Larry Pope became the new president of Smithfield Foods, which continued to grow with more international acquisitions.

Although Joe Luter IV left the company to pursue other interests, the Luter concern and care for the town of Smithfield continues.

“My father grew up there and there’s no place he loves more than Smithfield,” Luter IV said, adding that the family shies away from self-promotion but continues in its philanthropy .

The life-size bronze statues throughout the town, all the work of noted sculptor George Lundeen, were Joe Luter III’s gift to the town. Later Joe Luter IV and his siblings commissioned three new Lundeen sculptures honoring Joe Luter Sr., Joe Luter Jr. and Joe Luter III. The founding trio stand in a grassy area in the center of the riverfront Smithfield Foods campus.

The Luters have supported the town with numerous projects, including Windsor Castle Park, the Luter Sports complex and the Luter Family YMCA as well as in bringing the corporate headquarters back to Smithfield.

In 2018 when the company closed its aging smokehouse, the last in town, a wave of worry swept over Smithfield ham lovers. But no need to worry, according to Adrienne Taylor, Smithfield Foods’ associate public relations manager, who assured that each year the company continues to cure, age and smoke about 2200 Smithfield Genuine Hams within the town limits at the Smithfield North Facility on Church Street.